Types of Joint Movement

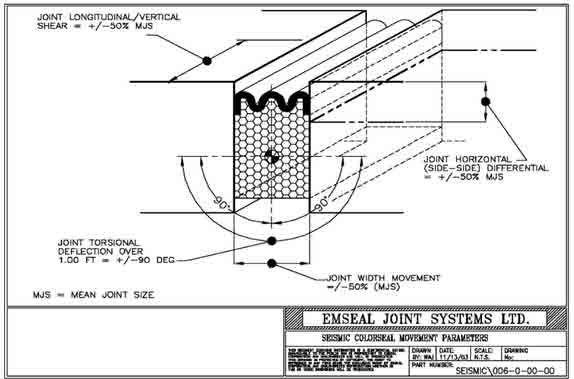

The different types and sources of joint movement to be considered in buildings and civil engineering structures can include:

- Thermal movement

- Static loading

- Dynamic loading, including vibration

- Wind-sway

- Subsidence

- Shear forces

- Seismic events …. etc., etc.

Whilst the widespread smaller type of movement joints are generally just designed for thermal movement, it is normal for most wider movement joints to be designed having to accommodate a combination of different sources of movement e.g. Thermal movement (heating-up and/or cooling-down), with additional movement from static and/or dynamic loading of the structure.

Complex movement joint design to accommodate movement in more than one plane

This is very much the situation in larger structures, as the bigger the structure, the bigger the movement joints may need to be, plus because of the total amount of different types of movement that must be accommodated, To keep the number of joints to a minimum is also frequently an objective e.g. for visual aesthetics, as well as to minimise potential damage e.g. in trafficked surfaces, so again the higher the joint movement capability requirements can be. As a result of all these bigger joint movement demands, the bigger the challenges there are in successfully accommodating this movement and in ensuring joint watertightness, together with any other simultaneous joint performance requirements e.g. fire resistance or vehicular trafficking. These aspects are discussed further below, and in the following pages of this website and with the appropriate Emseal solutions for different types of structure and their specific performance demands.

Additional Movement Joint Requirements

Watertightness and Additional Movement Joint Requirements

In most building and civil engineering structures, one of the most important wide and/or higher movement expansion joint requirements, whilst accommodating the defined levels of movement, is the simultaneous sealing against water ingress into the building and/or into the structure itself. This is as well as the many other demanding performance requirements that may also have to be met by the design and performance of wide and/or higher movement expansion joints and their joint sealing system. Additional performance requirements can also include everything from being required to provide external weathering resistance, add to or maintain the necessary fire resistance, withstand mechanical impact and abrasion resistance from traffic, to maintain the necessary chemical resistance or the acoustic and thermal insulation of the floor and / or wall assemblies they are part of, as well as many other specific demands in their locations and functionality within different types of structures and exposure situations.

The additional requirements for wider and/or higher movement expansion joints can therefore include:

- Watertightness

- Fire Resistance

- Impact & Abrasion Resistance (e.g. from pedestrian and/or vehicular traffic, or security demands etc.)

- Weathering Resistance (UV Light etc.)

- Chemical Resistance

- Many Other ‘Project Specific’ Joint Requirements e.g. colour, visibility (or not), no slip-hazards etc., etc.

Emseal produce expansion joint sealing systems that include solutions to accommodate all these different types and levels of movement, as well as all these different performance requirements, and in most combinations of these varied exposure and loadings.

The Emseal joint sealing solutions include systems with joint movement capability that is proven up to 100% of the joint width (also typically stated as +/- 50%), in addition to full resistance to the simultaneous additional exposure and requirements.

For example:

- to provide or maintain fireproofing and fire-resistance, some Emseal expansion joint sealing systems are now CE and/or ASTM certified for up to 4 hours fire resistance; as well as for direct vehicle trafficking, including to heavy goods vehicles (HGV’s) and the frequent traffic demands of car park ramps and decks etc.

- expansion joint sealing system solutions for submerged and/or permanently immersed expansion joints, and for joints with liquid exposure that includes aggressive chemicals.

- for modern public buildings and certain types of facilities from stadiums to prisons that can also benefit from innovative Emseal joint sealing systems that provide ‘pick-proof’ expansion joint solutions for high security areas.

- to support buildings being more sustainable and meeting modern standards with their low U-values (for heat loss through the material, lower the better) and high R-values (resistance to heat flow – higher the better), for increased thermal insulation such as Building Regulations Type L - Conservation of fuel and power, whilst ensuring continuity of a watertight seal for roofing and façade systems. These Emseal systems also provide high ratings for STC (Sound Transmission Class) and OITC (Outdoor/Indoor Transmission Class), which are measured in decibels (dB) and help to provide or maintain high levels of acoustic as well as the thermal insulation values.

For specific advice to solve the movement and expansion joint sealing requirements for your project, please call 01257 266696 or email us for advice: technical@nccinaction.co.uk